$3,288.31 – $4,078.76

Inclined powerhead for your grain bin unload system.

At Brock, we’re always getting input from the field and working to make sure our products keep up with customers’ changing needs. Incline powerheads are mounted on the unload tubes on all bin sweeps are known to have transition joints that require additional maintenance attention. Our newest update to the Brock 1500 Series Power Sweep improves this connection and enhances sweep durability.

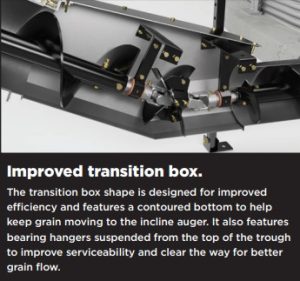

The transition box shape is designed for improved efficiency and features a contoured bottom to help keep grain moving to the incline auger. It also features bearing hangers suspended from the top of the trough to improve serviceability and clear the way for better grain flow

Twin u-joints provide smoother operation, keeping auger shafts in sync and improving reliability. Integrated flights are incorporated into the jointassembly to transfer grain more efficiently from the horizontal to the incline auger.

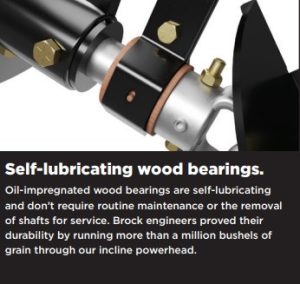

Oil-impregnated wood bearings are self-lubricating and don’t require routine maintenance or the removal of shafts for service. Brock engineers proved their durability by running more than a million bushels of grain through our incline powerhead.

Brock uses split wood bearings that don’t require removal of shafts for service. Split bearings are easy to replace and can save you considerable time and labor costs well down the road.

Brocks Inclined Powerhead Brochure: Brock Inclined Powerhead

| Size | 8"-10", 10"-12" |

|---|---|

| Number of Belts | 3, 4 |

Reviews

There are no reviews yet